A FEW WORDS ABOUT PVC AS A PIPE MATERIAL

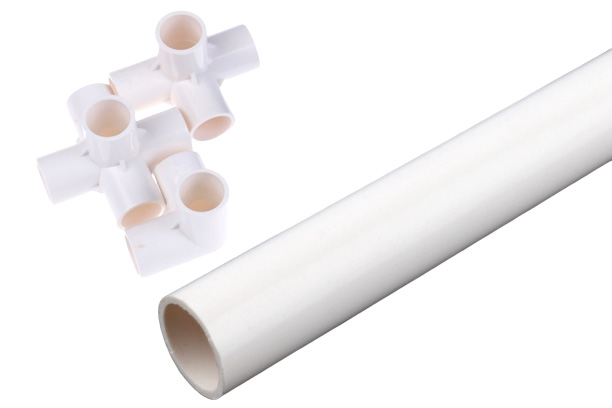

Of all the plastic materials available for piping systems PVC has been found to all possess the best combination of properties and economy. Poly Vinyl Chloride (PVC) is a thermoplastic used and approved worldwide as a dependable engineering material. PVC pipes are produced by mixing PVC resin (a petro-chemical product) with stabilizers, lubricants, pigments, fillers, processing aids and plasticizers

‘Hari Plaast‘ PVC PIPES & FITTINGS are manufactured conforming to various Indian & International standards like IS : 4985 , IS : 12818, ASTM- D- 1785, BS, DIN and ISO in various sizes ranging upto 315 mm in diameter in all classes and pressure rating.

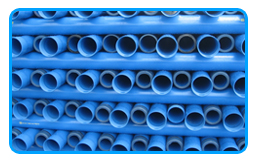

It produces PVC pipes for every conceivable applications from drinking water supply and bore well systems to transportation of abrasive slurries.

“Hari plaast” RIGID PVC PIPES FOR SOLVENT CEMENT AS WELL AS ELASTOMERIC RUBBER RING JOINTING

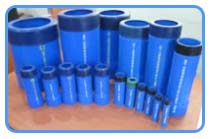

“Hari plaast” PVC CASING PIPES CONFORMING TO IS: 12818-1992

These pipes are manufactured as per BIS 12818-1992 and supplied in 2, 3 & 4 meters length with one end having male threads & the other end having female threads. Threads are V or trapezoids type and protection caps are provided on the threads to protect the threads in transit. Two types of pipes i.e. Shallow Well (C.S.) and Medium Well (C.M.) are available.

These pipes are manufactured as per BIS 12818-1992 and supplied in 2, 3 & 4 meters length with one end having male threads & the other end having female threads. Threads are V or trapezoids type and protection caps are provided on the threads to protect the threads in transit. Two types of pipes i.e. Shallow Well (C.S.) and Medium Well (C.M.) are available.Hari plaast” RIBBED SCREEN PIPES CONFORMING TO IS: 12818-1992

Hari Plaast PVC Ribbed Screen pipes have longitudinal ribs and transverse slots. These pipes are generally used in combined wells where normal Screen pipes does not work. These pipes carries BIS Certification mark and manufactured in lengths 1, 2, & 3 meters with one end having male threads and the other end having female threads. The slot width range for screens is 0.2mm,0.3mm,0.5mm,0.75mm,1.0mm,2.0mm & 3.0mm.

Hari Plaast PVC Ribbed Screen pipes have longitudinal ribs and transverse slots. These pipes are generally used in combined wells where normal Screen pipes does not work. These pipes carries BIS Certification mark and manufactured in lengths 1, 2, & 3 meters with one end having male threads and the other end having female threads. The slot width range for screens is 0.2mm,0.3mm,0.5mm,0.75mm,1.0mm,2.0mm & 3.0mm.“Hari plaast” PVC PLUMBING AND CASING PIPES MADE TO ASTM D 1785.

These pipes are manufactured as per ASTM D 1785 and supplied in 3, 5 & 6 meters length with one end having male threads & the other end having female threads. These pipes are well accepted by the users everywhere for plumbing, water distribution and particularly in deep tube well connection because of higher collapse strength.

These pipes are manufactured as per ASTM D 1785 and supplied in 3, 5 & 6 meters length with one end having male threads & the other end having female threads. These pipes are well accepted by the users everywhere for plumbing, water distribution and particularly in deep tube well connection because of higher collapse strength.“Hari plaast” SWR drainage system:

“Hari plaast” SWR pipes are manufactured in accordance with BIS specn No. IS: 13592 and are utilized in applications such as laboratory, chemical lines, overflow and waste discharge systems in chemical plants, waste lines in the food processing industry and effluent discharge in diary plants other than domestic drainage systems. Hari Plaast SWR pipes are available in 2,4,6 & 10 feet length in the range of 75, 110 and 160 mm OD.

“Hari plaast” SWR pipes are manufactured in accordance with BIS specn No. IS: 13592 and are utilized in applications such as laboratory, chemical lines, overflow and waste discharge systems in chemical plants, waste lines in the food processing industry and effluent discharge in diary plants other than domestic drainage systems. Hari Plaast SWR pipes are available in 2,4,6 & 10 feet length in the range of 75, 110 and 160 mm OD.BENEFITS OF “Hari plaast” PVC PIPE:

FIELD OF APPLICATIONS:

Plumbing & Drainage applications in homes, offices, hotels, residential complexes, commercial complexes etc.

Industrial

Industrial process lines. & R.O (Raverse Osmosis) / Water purifier plants. Salt water line. Aggressive fluid transportation. Sugar, paper and distillery. Coal washing and ash handing.

Others:

Water distribution lines and bore well applications.

PROPERTIES OF PVC

| GENERAL | TEST METHOD | UNIT | |

|---|---|---|---|

| Cell Classification | ASTM D1784 | 12454-B | — |

| Maximum Service Temperature (uPVC) | — | 60 | °C |

| Specific @ Gravity 73° F (uPVC) | ASTM D792 | 1.44+0.03 | — |

| Water Absorption in 24 hrs @77° F | ASTM D570 | 0.05 | % weight increment |

| Hardness, Rockwell | ASTM D785 | 110-120 | — |

| Hardness, Durometer D | ASTM D2240 | 80+3 | — |

| Hazen-Williams Factor | — | C=150 | — |

| MECHANICAL | |||

| Tensile Strength @73° F | ASTM D638 | >48.3 | MPa |

| Tensile Modulus of Elasticity @73 ° F |

ASTM D638 | >2758 | MPa |

| Flexural Strength @ 73° F | ASTM D790 | 14450 | psi |

| Compressive Strength @ 73° F (min) | ASTM D695 | 9600 | psi |

| Izod Impact, notched @73° F | ASTM D256 | <0.65 | ft-lb/in |

| Hydrostatic Desing Stress | ASTM D1785 | 2000 | Psi |

| THERMAL | |||

| Coefficient of Linear Expansion | ASTM D696 | 209×10-5 | In/in°F |

| Coefficient of Thermal Conductivity | ASTM C177 | 3.5×10-4 | (Cal)(cm)(cm2)(sec)(°C) |

| Heat Deflection Temp under load, | |||

| Annealed @1.82 MPa | ASTM 648 | >70 | °C |

| Specific Heat | ASTM D2766 | 0.25 | Cal / (gm°C) |

| Vicat Softening Temperature (uPVC) | IS 4985 | >80 | °C |

| FIRE PERFORMANCE | |||

| Limiting Oxygen Inbox (L.O.I.) | ASTM D2863 | 43 | % |

| Average Extent of Burning | ASTM D635 | <25 | mm |

| Average Time of Burning’ | ASTM D635 | <10 | sec |