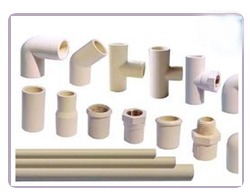

CPVC Pipes & Fittings

Cpvc Pipes & Fittings

Hari Plaast CPVC Pipes & Fittings are made from the specialty thermoplastic known as post Chlorinated Ploy Vinyl Chloride and met all the requirments of ASTM D 2846 and IS 15778:2007.The pipes and fittings are available in complete range from 1/2″ to 2″ sizes.The pipes are available in SDR 11 and SDR 13.5 pressure class and fittings are available in SDR 11 pressure class.

Field Of Applications

Hot and Cold water distribution in residential,commercial and public projects,high and low rise buildings,corporate houses and academic institutes,solar heater application etc.

Advantages

- Excellent resistance to corrosion and chemical attacks.

- Lowest bacterial growth.

- Tough and rigid material.

- No Scale, pit or leach formation

- Unaffected by chlorine in the water

- Hot and cold water compatible

- Low thermal expansion

- Fire resistance

- Simple and leak proof joints

- Maintenance free

- Cost effective

- Approved World wide.

Mechanical Properties

The principal mechanical difference between CPVC and PVC is that CPVC is significantly more ductile,allowing greater Flexure and crush resistance.Additionally,the mechanical strength of CPVC makes it a viable candidate to replace many types of metal pipe in conditons where metal’s susceptibility to corrosion.

Physical Properties

CPVC shares most of the features and properties of PVC.It is also readily workable,including machining,welding,and forming.Beacuse of its excellent corrosion resistance at elevated temperatures,CPVC is ideally suited for self-supporting.

Dimensions Of Hari Plaast Cpvc Pipes Made To Is 15778:2007/ASTM D 2846

Hari Plaast CPVC pipes and fittings are joined by the solvent cementing process a reliable joining technique field-proven for more than 40 years.When properly conducted,this method provides a strong,homogenous joining area in which the mating surfaces are chemically fused together,producing a strong,leak-tight seal when cured.Prior to solvent cementing,appropriate safety precautons should be taken.

Since quality of the solvent cement plays the important role and influences the joint strength it is recommended to use specially formulated solvent cement supplied the company for trouble free performance of the system.

| Nominal Dia (mm) | Outer Diameter (mm) | SDR 11 | SDR 13.5 | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Wall Thickness (mm) | Working Pr. Kgf/cm2 at | Wall Thickness

(mm) |

Working Pr. Kgf/cm2 at | |||||||

| Min | Max | Min | Max | 23’c | 82’c | Min | Max | 23’c | 82’c | |

| 15 | 15.8 | 16.0 | 1.7 | 2.2 | 28.10 | 7.0 | 1.4 | 1.9 | 22.50 | 5.6 |

| 20 | 22.1 | 22.3 | 2.0 | 2.5 | 28.10 | 7.0 | 1.7 | 2.2 | 22.50 | 5.6 |

| 25 | 28.5 | 28.7 | 2.6 | 3.1 | 28.10 | 7.0 | 2.1 | 2.6 | 22.50 | 5.6 |

| 32 | 34.8 | 35.0 | 3.2 | 3.7 | 28.10 | 7.0 | 2.6 | 3.1 | 22.50 | 5.6 |

| 40 | 42.1 | 41.4 | 3.8 | 4.3 | 28.10 | 7.0 | 3.1 | 3.6 | 22.50 | 5.6 |

| 50 | 53.9 | 54.1 | 4.9 | 5.5 | 28.10 | 7.0 | 4.0 | 4.0 | 22.50 | 5.6 |

Consumption Of Solvent Cement

| No.of fittings per Ltr. | 25 | 20 | 25 | 32 | 40 | 50 |

| Pipe Size (mm) | 1200 | 750 | 500 | 450 | 325 | 225 |

Set & Cure Times

Assembled joints must be allowed to set and cure properly prior to testing the system.Set and cure times are a function of type of cement used,pipe size,temperature,humidity,and tightness of fit.Drying time is faster for drier environments,smaller sizes,higher temperatures and tighter fits.The assemly must be allowed to set without any stress on the joint for one to five minutes depending on the pipe size and temperatue.Followiing the initial set period, the assembly can be handled carefully.Failure to do so will result in joint failure.

Curing Time For Operating/test Pressure Upto 12 Kgf/cm2

| Ambient Temp | Upto 32 mm | 4o to 50 mm |

|---|---|---|

| 17′ to 48’c | 1 hr | 2 hr |

| 5′ to 17′ | 3 hr | 4 hr |

| Upto 5’c | 8 hr | 16 hr |

Chemical Resistance Of Cpvc

| Chemicals | Concentration | 200c | 600c | 800 c |

|---|---|---|---|---|

| Hydrochloric Acid | 20% | Excellent | Excellent | Good |

| Hydrochloric Acid | 35% | Excellent | Excellent | Good |

| Nitic Acid | 40% | Excellent | Fair | Fair |

| Nitic Acid | 60% | Good | Fair | Not good |

| Sulphuric Acid | 30% | Excellent | Good | Good |

| Sulphuric Acid | 50% | Excellent | Good | Not good |

| Sulphuric Acid | 100% | Good | Not good | Not good |

| Acetic Acid | 60% | Excellent | Fair | Fair |

| Acetic Acid | 95% | Good | Not good | Not good |

| Carbonic Acid | 100% | Excellent | Fair | Fair |

| Caustic Soda | 40% | Excellent | Excellent | Good |

| Caustic Soda | 60% | Excellent | Excellent | Good |

| Sodium Chloride | Saturated | Excellent | Excellent | Good |

| Sodium Carbonate | Saturated | Excellent | Excellent | Good |

| Sodium Sulphates | Saturated | Excellent | Excellent | Good |

| Hydrogen Peroxide | <30% | Excellent | Excellent | Not good |

| Ammonium Carbonate | Saturated | Excellent | Excellent | Good |

| Methanol | 100% | Excellent | Fair | Not available |

| Isopropanol | 100% | Excellent | Good | Good |

| Butanol | 100% | Excellent | Good | Fair |

| Glycerin | 100% | Excellent | Excellent | Excellent |

| Acetone | 100% | Not available | Not available | Not available |

| Methyl Ethyl | 100% | Not available | Not available | Not available |

| Ketone | 100% | Not available | Not available | Not available |